PROTECT STORED FUEL, PREVENT CORROSION, PREVENT MICROBIAL GROWTH

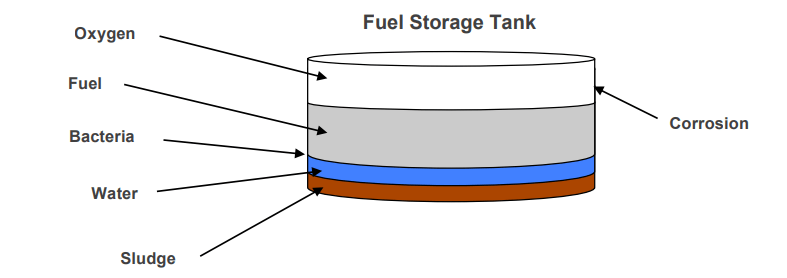

Water. Water seeps in due to rainwater, condensation, and is sometimes used to pump out fuel. Water in fuel hinders combustion and performance. Most storage tanks have a layer of water on the bottom, which should be frequently drawn off. (MotorSilk® Diesel Additive MSDA is an emulsion so does not mix with the water, instead it reacts with oxygen and water present to bond with the metal tank and thereafter protect it).

Sludge. Formed from gums and lead in gasoline, and waxes in diesel fuel. Sludge must be removed, as build up may put fuel out of specification if it mixes in. (MotorSilk® Diesel Additive MSDA acts as a dispersant, eliminating particles and contaminants from the fuel, and as a polymerization retardant, prevent molecular chaining of hydrocarbons).

Oxidation. Both gasoline and diesel fuel can oxidize during storage. This is the slow chemical combination of diesel and gas with oxygen from the air. These catalyze with heavy metal ions, such as copper, that may be present in the fuel, resulting in contamination of the fuel. (MotorSilk® Diesel Additive MSDA inherently prevents catalytic oxidation).

Corrosion. Corrosion occurs due to the presence of moisture and air in the fuel distribution and storage system. Rust particles degrade fuel quality and block fuel filters. (MotorSilk® Diesel Additive MSDA is a corrosion inhibitor to prevent internal corrosion and fouling of fuel tanks.

Microbiological Contamination. Bacterial and fungal growths can sometime lead to operational problems such as cloudy fuel and filter blocking if storage tanks are not cleaned regularly. The organisms live in water bottoms of tanks and feed on the fuel at the interface. (MotorSilk® Diesel Additive MSDA acts as a bio stat eliminating bacteria from the fuel).

WHAT CAN I DO TO TREAT MY STORAGE TANKS?

Use MotorSilk® Diesel Additive (MSDA) with Boron-CLS-Bond® as an additive and treatment for your storage tanks for all diesel fuels. Diesel treated with Boron-CLS-Bond® acts as an effective bio stat. At a ratio of 1:1000, a small volume in your whole tank will eliminate microbiological growth from in fuel and keep your tank and your fuel healthy, not only retaining a high cetane number but improving your cetane numbers by 8 to 10 points. In addition, that diesel will then add additional benefits to your engine, establish lubricity for low sulfur fuels, reducing start time, reducing injector pump wear, keep the injectors clean to optimize their spray patterns; all working together to improve your fuel efficiency.

MotorSilk® Diesel Additive lowers Green House Gas [GHG] and particulate matter emissions, is biodegradable, and is the only Fuel additive that is ISO 14064-2 process compliant, validated and verified by the Canadian Standards Association (CSA) for reduction of GHG emissions by means of reducing the amount of fuel burned.

MOTORSILK® MSDA – APPLICATION PROCEDURE FOR STORED FUEL TANKS

Application Ratio

Initial Treatment

1:750 – dosing for the initial treatment when treating a metal/steel fuel tank (should be treated when the tank is full), is at 1/750 of the capacity of the storage tank, e.g. for a 50,000 litre “at capacity” stored fuel tank, initial treatment would be 67 litres. The Boron-CLS-Bond® will react with, clean and bond with the metal/steel interior of the tank.

Subsequent Treatment

1:1000 – for subsequent dosages; for the new fuel added as the tank does not need to be re-treated.

Benefits

- Cetane number in low sulfur diesel improves by 8 to 10

- Removes varnish and fouling on injectors

- Enhances lubricity of low sulfur fuels

- Reduces starting time

- Reduces injector pump wear

- Lower Green House Gas [GHG] and particulate matter emissions

- Breaks down all existing microbiological growth in the tank and prevent new biological growth.

- Keeps your tank, your fuel flow, pumping system and your fuel healthy

- Only additive that is ISO 14064 process compliant for reduction of [GHG] emissions

- Biodegradable